i-Dositecno is offering on

the market high technologies for sterile

filling systems, proposing to customers highest technology

for ophthalmic solutions and injectable solutions. All

sterile machines are done with best materials to achieve maximum quality and

highest accuracy.

i-Dositecno also offers documentation packages developed by own engineers with

a complete DQ of i-Dositecno machine, IQ and OQ documentation. As well as, an

accurate user’s manual, materials certificate and mechanical and electrical

manual.

i-Dositecno has developed systems to fill vials and syringes for injectable

solutions, covering a huge range of product from 0,1ml till 500ml in vial and

0,1ml in syringes till 20ml. For ophthalmic solutions, i-Dositecno offers a

huge range of bottles up to 500ml, with standard eye-drops introduction and

screw capping, or systems like new aptar filtered cap. Filling proposed systems

starts from peristaltic pumps till complex ceramic rotary pump with CIP/SIP

system integrated. The sterile filling solutions are offered with a high

technology software in compliance with CFR21 part 11, with track and trace

control, IPC control (Inline Process Control).

All these things make i-Dositecno as a company with high added value on sterile

market with a huge range of machinery covering medium speed solutions,

with high sterile pharma solutions.

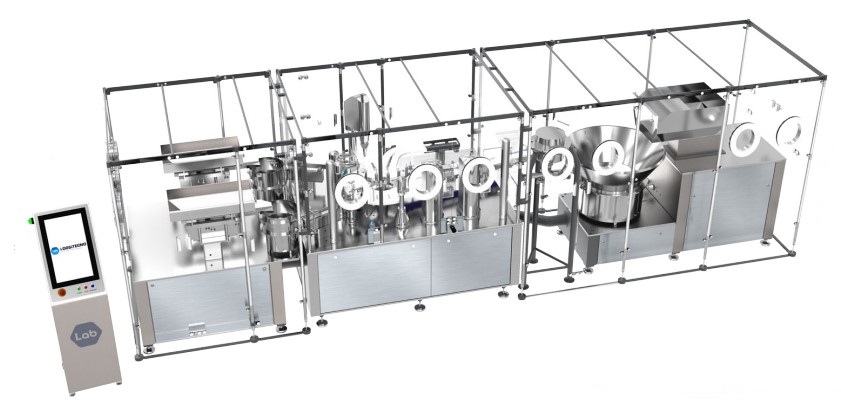

STERILE

OPHTHALMICS

Ophthalmic market is a very demanding market, with high standard requirements. i-Dositecno is offering a very high standard solution for medium and low speed solutions, but with very high requirements. The speed range covers till 9.000u/h, and the equipment is offering a complete sterile solution, from filling system to the special materials requirement for this market.

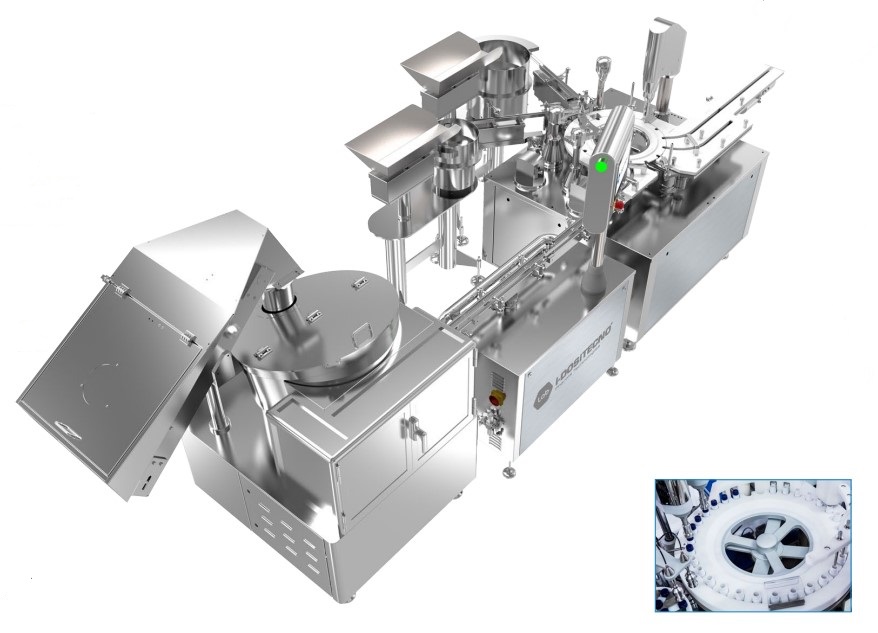

STERILE

INJECTABLES

Injectables

market is a very

demanding market, with high standard requirements. i-Dositecno is offering a

very high standard solution for medium and low speed solutions, but with very

high requirements. The speed range covers till 9.000u/h. In this product range

i-Dositecno can offer maximum benefits like Isolators for high containment

solutions, oRAB’s and cRAB's, IPC control with check weighing of 100% of the

production, CFR 21 part 11 compliance and smooth and accurate production.

Leave a Comment