Magnetic stirring is used in a number of common

laboratory procedures, yet the importance of selecting the best stirring bar

for each particular application is often overlooked. The drive magnet, vessel

shape, viscosity and abrasiveness of the materials should all be considered

when choosing the size, shape and materials (coating and magnet) of the magnetic

stirring bar in order to achieve effective, efficient stirring results.

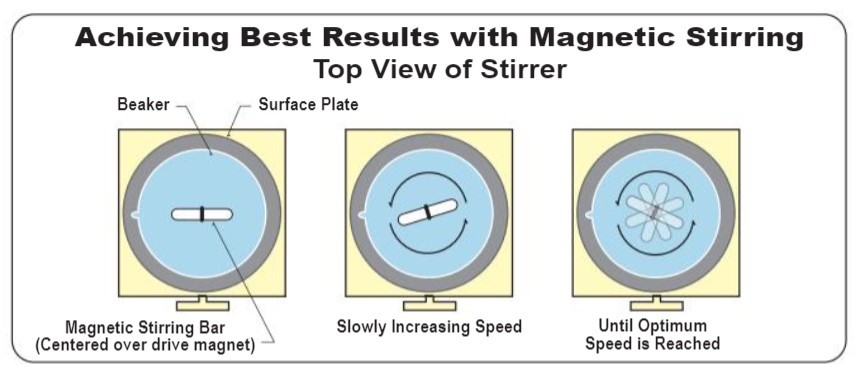

When a magnetic stirring bar has been placed in a container with solution, it

should be positioned directly over the centre of the drive magnet. The stirring

speed should be increased slowly, until the desired vortex pattern is achieved.

Should the magnetic stirring bar lose its coupling with the drive magnet

because of the speed of the drive magnet, viscosity of the fluid, or an improperly

selected stirring bar length, it is said to have “spun-out”.

Vertical distance between the drive magnet and the stirring bar should be kept to

a minimum for the best coupling and stirring efficiency. Therefore, the

containing vessel should be as thin as practical.

The selection of the shape of the magnetic stirring bar also influences the

resulting vortex in that multi-sided shapes may be more efficient in moving

solutions and certain shapes have been designed to provide a tailored fit in

specialty vessels such as test tubes, cuvettes and spectrophotometer cells.

Magnetic stirring bars are generally made of ALNICO (an alloy of aluminum,

nickel, iron and cobalt) magnets encapsulated in an FDA approved PTFE coating. In

addition, magnetic stirring bars also use high energy magnetic materials, such

as Samarium Cobalt which increases strength of coupling with a drive magnet and

helps to reduce spinout when mixing viscous solutions or mixing at high speeds.

Guide for

choosing Spinbar® Magnetic Stirring Bar

|

Applications |

General Stirring Applications |

High Temperature Stirring |

Viscous Solutions High Speed Stirring |

|

Brand

/ Type |

Spinbar® Teflon PTFE |

Spinbar® Pyrex Glass |

Spinbar® Rare Earth Samarium Cobalt |

|

Magnetic

Type |

Alnico |

Alnico |

Samarium Cobalt |

|

Covering |

Teflon® PTFE |

Clear Pyrex® Glass |

Teflon® PTFE |

|

Features

/ Benefits |

Wide selection of shapes and sizes to fit vessels of all types;

Individual shapes create different vortexes for efficient and effective

stirring |

Heated stirring applications up to 274oC (525oF) |

Reliable Magnetic Coupling – Superior magnetic energy reduces frequency

of spinout in the most vigorous applications |

|

FDA Grade, USP Class VI Teflon® brand PTFE coating – Superior Chemical

Compatibility |

Glass casing has zero absorption and porosity |

FDA Grade, USP Class VI Teflon® brand PTFE coating – Superior Chemical

Compatibility |

|

|

Color Selection for color-coding work processes |

|

Distinct Color – Green color lets you quickly identify Spinbar® Rare

Earth Samarium Cobalt |

All Spinbar® and other Teflon® PTFE Coated Magnetic Stirring Bars are manufactured in a registered ISO9001:2015 facility, as verified by SGS Certification.

Leave a Comment